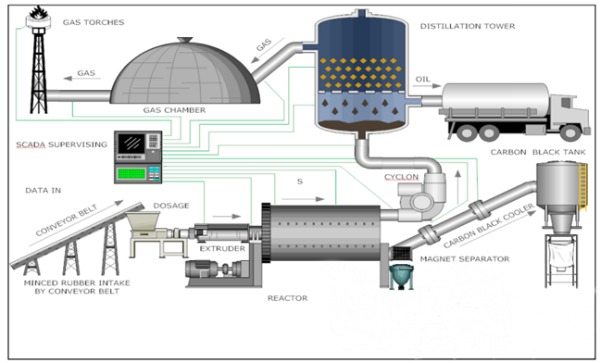

In association with EROM we provide a unique patented technology for the recycling of waste tires. This technology represents a faster, more efficient dissimilation process of waste tires free of emissions and other pollutants harmful to the environment, together with very low energy consumption and highly marketable byproducts.

This innovative technology, based on the gasification of waste tires, is state of the art and has been developed according to complex, high ecological and technological standards, all of which taken together represents an additional considerable advantage over other, less advanced technologies.

A turnkey gasification recycling plant designed and delivered by Erus means:

• low-cost investment

• all output byproducts are marketable

• fast return on investment

• CE certificate

An unique waste tire recycling system is:

• closed

• continuous

• ecological

• safe

• profitable

• applicable all over the world

Recycled output products and applications:

• Recovered gasification oil can be used as an energy source in combustion engines, industrial boilers, power plants and large-scale heating systems.

• Carbon black can be (re)used in the rubber industry to produce new rubber, or as a lining material in printing and paint production.

• Scrap steel can be reused by the steel industry.

• Gas is used for heating the reactor in the recycling process.

All output byproducts are marketable; except the gas, which can be used as a process energy source instead of electric power.

Features of the system:

• System is designed and built for operation 24h/7 days

• Daily system input capacity of 20–24 tons/day of waste tires

• Daily system output capacity of 10,000–10,500 l/day of recovered gasification

oil, and 10,000–11,000 kg/day of carbon black

• Energy consumption of 12 kW/h steady consumption of running system

• Minimal required crew of one supervisor and one operator per shift

Minimum system installation requirements:

• Closed industrial space, 20 m length, 15 m width, 6 m height

• Separate space for gas chamber for 200 m3 reservoir

• Electrical power supply, min. 40 kW/h consumption for start preheating (4 hours) and 12 kW/h running power

• Reservoir for recovered gasification oil (or truck tanker)

Advantages of the system:

• CE certificate

• Low operating costs

• Fully automated

• Closed, continuous feed system with increased efficiency

• Optimum system size and capacity, suitable for smaller spaces

• Continuous process ensures high quality of output byproducts

• Low energy consumption

• Only one supervisor and one operator per shift required

• Non-condensable gases are reused in the process

• Maintenance service: four times annually for three days each; 12 days in total per year

• SCADA electronic guided control system, access and monitoring over the internet

• No pollutant emissions

• Fast return on investment (ROI), only two years in Europe

• System is ready to work in cogeneration link (three types of generation: electricity, heating

and cooling)

• Two-year warranty

Scheme of waste processing device (source: Erus d.o.o.).

Annual system capacities:

• Input of waste ground tires: ca. 8,000 tons per year

• Output of recovered oil: ca. 3.3 million liters per year

• Output of carbon black: ca. 3.6 million kg per year

• Output of steel: ca. 560 tons per year

Please contact us for more information.